litho printing for Magazines, Leaflets, and Pamphlets

litho printing for Magazines, Leaflets, and Pamphlets

Blog Article

A Comprehensive Overview to Recognizing Litho Printing Techniques

The globe of litho printing, a method stemming from the late 18th century, is a remarkable mix of history, science, technology and art. Stay with us as we journey right into the captivating realm of litho printing.

The Historic Advancement of Litho Printing

The historical trajectory of litho printing, a critical advancement in the realm of communication, is a fascinating tale of human resourcefulness. The process developed with the development of the rotating press, which greatly boosted productivity. Each phase of litho printing's development showcases humankind's unrelenting quest of performance and high quality in aesthetic communication.

Deciphering the Scientific Research Behind Litho Printing Inks

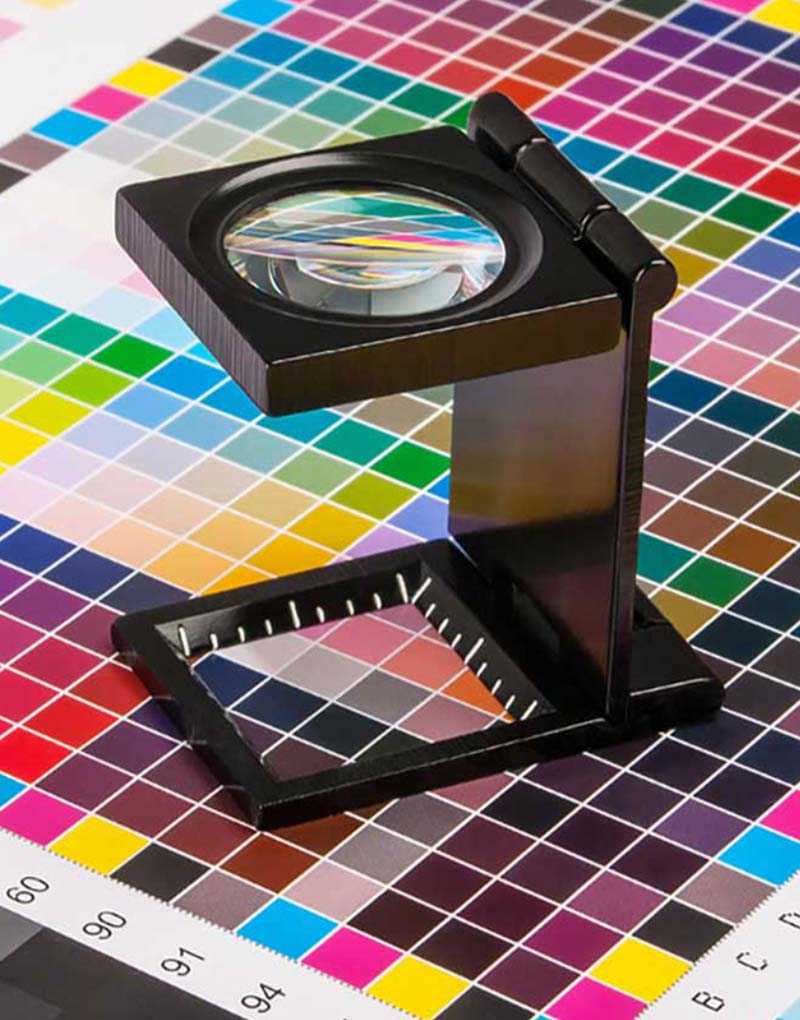

Moving onward in the expedition of litho printing techniques, the emphasis currently shifts to the scientific research behind litho printing inks. The make-up of these inks, their drying procedure, and color mixing techniques create the foundation of this intricate art type. Understanding these elements is critical to mastering the craft and attaining the wanted print outcomes.

Composition of Litho Inks

In lithographic printing, the basic role of litho inks can not be overemphasized. The structure of litho inks differs relying on its purpose, but normally, they include two primary components - pigments and automobiles. Pigments, the color-providing components, are finely ground particles put on hold in the automobile, a liquid that lugs the pigment onto the printing surface. The vehicle is an intricate mixture of materials, solvents, and oils, which influence the ink's drying time, adhesion, and gloss. Additionally, various additives exist to improve specific residential properties like flow, drying out, and resistance to ecological impacts. Each component plays a critical part in the final print's top quality, making the exact formulation of litho inks a complex science.

Ink Drying Process

From the composition of litho inks, interest turns to the fascinating procedure of ink drying out. The drying out process is vital, as it affects the last print's high quality and durability. 2 primary techniques are used in litho printing: oxidative drying out and absorption. Oxidative drying out entails the ink responding with oxygen in the air to develop a difficult, completely dry movie. This method provides a resilient surface, but can be slower contrasted to absorption. Absorption, on the other hand, includes the ink seeping into the paper fibers, which is a faster process yet can cause much less lively shades. The choice between these approaches is reliant upon variables such as print rate requirements, the paper type utilized, and the wanted coating.

Color Combining Techniques

While the drying process plays a crucial function in litho printing, the scientific research of shade blending techniques holds equivalent relevance. The science behind litho printing inks also takes right into account the openness of the ink, which impacts how shades overlay and mix.

The Art and Layout Components in Litho Printing

Litho printing takes a breath life right into art and style through its unique aspects. Litho printing fits a range of shades, making it possible for artists to develop vivid and vibrant prints. This mix of accuracy and flexibility makes litho printing a preferred option for several musicians and developers.

Modern Applications of Litho Printing Strategies

Litho printing strategies have actually found extensive use in the modern commercial market. Its influence and relevance remain to grow with the arrival of brand-new advancements and modern technologies in the field. This area will certainly explore these contemporary applications and the transformative role they play in the printing industry.

Business Litho Printing Makes Use Of

Litho printing continues to be a crucial component of the business market. High-volume printing jobs, such as the production of publications, papers, and product packaging, depend on litho printing for its capability to provide superior picture top quality and price effectiveness. Litho printing also gives a broad shade spectrum, superior to that of electronic printing.

Innovations in Litho Printing

Pressing the boundaries of traditional methods, contemporary advancements have fueled a host of advancements in litho printing. One popular growth is electronic litho printing, which integrates the merits of electronic innovation with litho's premium outcome. These developments highlight the enduring importance of litho printing in the modern-day world.

Discovering the Refine of Litho Printing: Action by Step

Difficulties and Solutions in Contemporary Litho Printing

In spite of the precision and practice site link that litho printing happily maintains, it is not without its set of modern difficulties. Digital litho printing enables for economical brief runs and simple customization, addressing the issue of variable information. Hence, while there are challenges, the litho printing sector is proactively adjusting to satisfy them head-on, guaranteeing its importance in the future.

Conclusion

Finally, litho printing, with its abundant background and clinical complexities, holds a significant area in the print industry. As the overview exposes, it's a synthesis of art and modern technology, with modern developments ensuring its importance. The sector faces obstacles that require cutting-edge solutions, with an emphasis on automation and sustainability. The future of litho printing depends upon its capacity to adapt to these altering demands, affirming its long-lasting value in a developing market.

Report this page